What is 5S

“Success each day should be judged by the seeds sown, not the harvest reaped.”– John Maxwell

Introduction

For any ceremony in the family like marriage, the key focus is that all the rituals should happen systematically, the guest should enjoy the entire function and the complete marriage process should be executed seamlessly. To ensure that a lot of planning and deliberations happen prior to the marriage and closed review & monitoring is done to ensure that the planned arrangement is effectively implemented.

Read More: https://bit.ly/KaizenMasaakiImai

Objective

5S is a five-step methodology for creating a more organized and productive workspace: Sort, Straighten, Shine, Standardize, and Sustain. It serves as a foundation for deploying more advanced lean production tools and processes.

Taiichi Ohno and Shigeo Shingo popularised the method as part of the original Toyota Production System that laid lean manufacturing foundations.

Once you read this blog, you will understand the true meaning of 5S, how to implement it at your workplace successfully, the goal of 5S, if 5S is expensive, why it important and the possible benefits.

Read More: https://bit.ly/DOJOCentre

Definition:

Competence (ISO 9000: 2015, Cl 3.10.4): Ability to apply knowledge and skills to achieve intended results

Skill (ISO 30401: 2018, Cl 3.30): Learned capacity to perform a task to a specified expectation

Knowledge (ISO 30401: 2018, Cl 3.25): Human or organizational asset enabling effective decisions and actions in the context

Read More: https://bit.ly/OrganizationKnowledge

Detailed Information

What is 5S?

5S is a system for organizing spaces so work can be performed efficiently, effectively, and safely. This system focuses on putting everything where it belongs and keeping the workplace clean, which makes it easier for people to do their jobs without wasting time or risking injury.

5S is often summarized by the philosophy “a place for everything and everything in its place.”

5S is often summarized by the philosophy “a place for everything and everything in its place.”

Saying that 5S is just about cleaning is like saying yoga is just about stretching.

5S Translation

The term 5S comes from five Japanese words:

- Seiri (Sort)

- Seiton (Set in Order)

- Seiso (Shine)

- Seiketsu (Standardise)

Shitsuke (Sustain)

Shitsuke (Sustain)

| Japanese | Translation | English | Definition |

| Seiri | Organize | Sort | Eliminate that which is not needed |

| Seiton | Orderliness | Set in Order | Organize what remains after sorting |

| Seiso | Cleanliness | Shine | Clean and inspect the work area |

| Seiketsu | Standardize | Standardize | Write standards for maintaining Seiri, Seiton & Seiso |

| Shitsuke | Discipline | Sustain | Consistently apply the first 4S standards |

Read More: https://bit.ly/ROI-Training

5s in Detail:

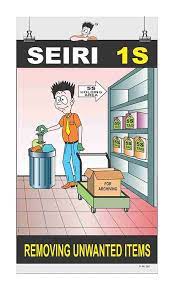

Seiri (Sort)

Seiri (Sort)

- What does it mean?

- Remove everything that is not necessary from the work area. Separate required tools, materials, and instructions from those that are not needed. Example: Summer and winter clothes, obsolete procedures, worn out tools, non-moving/slow-moving inventory, old biodata, obsolete software

- Why it is important?

- It enables us to have a more productive workspace by removing unneeded clutter and eliminating distractions, which will help to open up space that can be used for other things. Example: More storage space in the hard disk, more floor space for adding new machines, avoiding mixing of setup pieces with good pieces, control mixing of rejected pieces with ok pieces, easy to find the right spices in the kitchen

- How to implement it?

Sorting items into four categories:

- Items needed in the area: Measuring instrument for moulding

- Items needed in another area: Measuring instrument for press shop, sleepers in the rack

- Items not needed: Old, obsolete, love letters, old greeting cards, identification of material by the red tag

- Items may be needed: Machine manual, old bills, obsolete Purchase Order

- Example: Waste material, obsolete files (soft & hard), duplicate material/tools, rejected material

Seiton (Set in Order)

What does it mean?

What does it mean?

- “Place for everything and everything in its place”. Sort and organize all tools, equipment, files, data, material, and resources for quick, easy location, and use. Label all storage locations, tools, and equipment. Example: Files in the computer, tooling for the maintenance, WI for the operator, KPI for the engineer, easy retrieval of the spices in the kitchen!

- Why it is important?

- It enables every item to have a specific place where it can be easily found (effective visual management) and to which it can be easily returned. It reduces the waste from excess motion as items are placed in more ergonomic locations. Example: Operator working in the assembly line (ergonomically), Easy retrieval of the desired document by the finance department, Student can easily find the right textbook, quick retrieval of the driver’s license from the mobile phone

- How to implement it?

To systematically organize the available items, the following can be done

- Easy access to frequently used items: Books to be read today, the material which needs to be moulded today, the samples which have to be despatched to the customer

- Group similar items in one place: Drawings can be stored at one location, and calibration reports for each month in one folder

- Visualize the items: Shadow board for the tools: Less space, quick retrieval, Inventory Control with different colour codes (minimum and maximum inventory)

- Example:

- Colour coding

- Shadow boxes for the tools

Read More: https://bit.ly/TrainerCompetency

Seiso (Shine)

Seiso (Shine)

- What does it mean?

- Clean and remove all trash, grease and dirt. Cleanliness provides a safe workplace and makes potential problems noticeable. Example: oil/water/air leaks, loose parts, paperwork or material, loose electrical wires, to look like a 5 Start Hotel, the specific timeframe in every shift to clean the machines and shop floor

- Why it is important?

- In a clean work environment, it is much easier to spot emerging issues such as fluid leaks, material spills, metal shavings from unexpected wear, hairline cracks in mechanisms, any missing question which is not yet answered, better speed of the computer

- How to implement it?

- Use appropriate tools like cleaner, mop, brush, wax etc.

- Clean the working area: Cleaning with meaning and cleaning is an inspection

- Inspect and check if any maintenance, repair or update is needed

- Example:

- Investigate a recurring unclean spot

- Examine the wear of the tools

- Seiketsu (Standardise)

What does it mean?

What does it mean?

- Establish schedules and set expectations for adherence. Engage the workforce to systematically perform steps a, b, and c above daily to maintain the workplace in perfect condition as a standard process. Example: Traffic Lights (Red, Green and Yellow), USB Port, Colour code in the factory (Fire: Red, Water: Blue, Danger mark), colour code of the different grades of the steel

- Why it is important?

- Standardize makes 5S repeatable. It transforms 5S from a one-off project to a reproducible set of activities. It should not be one-time activity but implemented every time

- How to implement it?

- Capture the essence

- Prepare short checklist

- Simplify the task by role, shift, and frequency (daily, weekly)

- Example:

- Implementation checklist

- Audit checklist

- Prepare a schedule

- Use photos as training material

Shitsuke (Sustain)

What does it mean?

What does it mean?

- Build organizational commitment to consistently apply the first 4 standards so that it becomes the core organizational values and a habit.

- Why it is important?

- Iterative first 4 steps help the organization and individuals to engrain the concept of 5S and ensure further and continued progress. Provide training, divide the entire factory/office into the different zone for focused attention, periodic audit

- How to implement it?

- Create a schedule

- Instruct employees how to conduct 5S task: Fixed point photography

- Adapt as necessary

- Example:

- Hold demonstration meeting

- Teach how to conduct 5S audits

- Respond to mistakes with training

Read More: https://bit.ly/Kirkpatrick4LevelModel

Who Should Participate in 5S?

EVERYONE

If a department is starting 5S, managers and all other employees should be included. If anyone is left out, this could lead to confusion or it will give a message to the employees that it is not their ownership. When people see their superiors taking 5S seriously by participating in it, they’ll be more likely to take it seriously, too.

It is possible that some people will play a bigger role in 5S than others, which is fine. There might be 5S coordinators who are in charge of installing and maintaining 5S labeling, keeping track of assigned tasks, or introducing new department members to the 5S system. These people will obviously spend a lot of time thinking about 5S compared to others. Everyone should think about 5S regularly, though. 5S might initially take place as an event, but ideally, it becomes a part of daily work for everyone.

Read More: https://bit.ly/TraningNeedIdentification

Why 5S is Important?

Adherence to 5S standards is considered the foundation of Total Productive Maintenance (TPM) and an integral part of the Toyota Production System (TPS). 5S also creates a platform from which Kaizen (Improvement) activities can be launched.

Adherence to 5S standards is considered the foundation of Total Productive Maintenance (TPM) and an integral part of the Toyota Production System (TPS). 5S also creates a platform from which Kaizen (Improvement) activities can be launched.

While 5S was first developed in the context of the automotive industry (Toyota), it is now widely considered an essential element of any lean manufacturing program, regardless of industry and sector.

The truth is that 5S is a low-investment, high-impact lean manufacturing tool. It engages everyone in the organization (irrespective of position and level) in “owning” their workspace and helps to instill a culture of quality, productivity, and improvement.

Read More: https://bit.ly/CompetencyMapping1

If 5S is Expensive to Implement?

Business leaders considering using 5S may wonder if 5S is expensive to implement. Generally, it’s not. There may be an up-front investment in tools like floor marking tape and labels, and some time does need to be spent on training and on 5S activities, which takes up employees’ time. In the long run, though, 5S makes processes run more smoothly, improves productivity, reduces wastages, and creates a better work environment and those things usually save businesses money.

Read More: https://bit.ly/CompetencyRequirement

Benefits of 5S

5S is an excellent way to minimize the 7 wastes of Lean (also known as Muda). It protects the workplace from getting cluttered. Therefore, it is an effective way to reduce the waste of:

5S is an excellent way to minimize the 7 wastes of Lean (also known as Muda). It protects the workplace from getting cluttered. Therefore, it is an effective way to reduce the waste of:

- Motion – by reducing the distance covered to acquire a tool

- Waiting – by minimizing the time wasted waiting for a tool to be acquired

- Inventory – by removing any unnecessary equipment from the workplace

Some of the Key Benefits include

- Reduced costs

- Higher quality

- Increased productivity

- Greater employee satisfaction

- A safer work environment

Read More: https://bit.ly/EmployeeSatisfaction1

Industry Challenges:

How often the top management sets the target related to QCD (Quality, Cost, Delivery) to monitor the effective implementation of 5S?

How often the top management sets the target related to QCD (Quality, Cost, Delivery) to monitor the effective implementation of 5S?- How often 5S is considered a tool for improving productivity, enhancing the quality and reducing waste rather than cleaning the shop floor?

- How often the result of the effectiveness of the 5S implementation is a key input to the management review?

Read More: https://bit.ly/DifferenceCoachingMentoring

References:

ISO 9001: 2015

ISO 9002: 2016

ISO 9004: 2018

IATF 16949: 2016

Industry Experts

This is the 173rd article of this Quality Management series. Every weekend, you will find useful information that will make your Management System journey Productive. Please share it with your colleagues too.

In the words of Albert Einstein, “The important thing is never to stop questioning.” I invite you to ask anything about the above subject. Questions and answers are the lifeblood of learning, and we are all learning. I will answer all questions to the best of my ability and promise to keep personal information confidential.

Your genuine feedback and response are extremely valuable. Please suggest topics for the coming weeks.

Recent Comments