7 Step Problem Solving Technique

“ A problem is a chance for you to do better” — Duke Ellington

Introduction

We generally pray to God not to give any problem but problems are part and parcel of our lives. Instead, we can pray to God to give us the strength and patience to deal with any challenges in our professional and personal life.

Objective

The purpose of a quality management system is to help businesses improve their abilities to consistently meet customer or regulatory requirements. A major component of a successful system is a corrective action program that adequately addresses nonconformances. Quality pioneer W. Edwards Deming introduced the Plan-Do-Study-Act (PDSA) cycle as a planning, implementation, and continuous improvement tool.

In the problem-solving technique (like the 8D Model),

In this article, we learn how a seven-step problem-solving technique can be effectively implemented.

Definitions (ISO 9000: 2015):

Complaint (clause 3.9.3): Expression of dissatisfaction made to an organization related to its product or service or the complaints handling process itself where a response or resolution is explicitly or implicitly expected.

Corrective Action (Cl 3.12.2): Action to eliminate the cause of nonconformity and to prevent reoccurrence.

Correction (Cl 3.12.3): Action to eliminate a detected nonconformity

Complainant (clause 3.1; ISO 10001: 2018): Person, organization or their representative making a complaint.

Read More: https://bit.ly/Step1DefineProblem

Detailed Information:

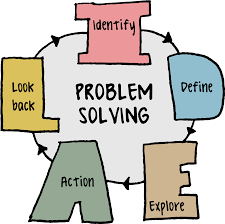

Effective problem solving doesn’t mean going away and coming up with an answer immediately. Instead, you should look at problem-solving more as a process with several steps involved that will help you reach the best outcome.

The following are the 7 key steps for problem-solving.

- Define the Problem

- Correction, Containment, Interim Action

- Root Cause Analysis: 3 Layered 5 Why Analysis (3L5Y), Ishikawa Diagram

- Implementation of Corrective Action

- Effectiveness Evaluation

- Horizontal Deployment (Yokoten: Japanese)

- Documentation, Lesson Learned and Promotion of Awareness

Read More: https://bit.ly/ProblemSolvingTechnique

Example:

100 assemblies (moulded components) rejected at the customer end (OEM) due to fitment issue

Read More: https://bit.ly/CorrectionContainmentInterim

- Define the Problem:

The key objective should be to define the problem as accurately as possible by using a CFT approach. Author Robert A. Humphrey tells us that “An undefined problem has an infinite number of solutions.” The more accurate and focused your definition, the closer you are to a solution.

Kipling Method named after Rudyard Kipling’s poem “I keep six honest serving-men,”

| 1 | What is the problem? | Defect: Crack on the front

Part number: abc Drawing: def Model: ghi Quantity: xx |

| 2 | Why is the problem important? | Repeated: Yes/No

Safety/Critical Characteristics/ Routine |

| 3 | When did the problem arise and when does it need to be solved? | Dated: xx.xx.xxxx

Shift: 1/2/3 Completion date: xx.xx.xxxx |

| 4 | How did the problem happen? | Visual/Fitment/Function

Operator/Inspector Name |

| 5 | Where is the problem occurring? | Customer: jkl

Location: mno |

| 6 | Who does the problem affect? | End-user/Next Process/Final Assembly

Legal Requirement Any other Stakeholder |

Read More: https://bit.ly/RootCauseAnalysis3L5Y

- Correction, Containment, Interim Action

There can be 5 possible actions that can be taken for any material/product which is rejected internally or externally. They are

- Segregation: Containment

- Rework: Correction

- Repair: Correction

- Use as it is (Concession): Interim Action

- Scrap

Correction: Action to eliminate a detected nonconformity, not a corrective action, simply corrects the non-conformity, does not address the cause of the problem.

Example:

In the moulding process, if the flash is coming in the moulded component which is not desired, we may add a process to cut the flash till the time we could find a root cause of the problem and can take action on the cause so that flash (nonconformity) can be eliminated.

Containment: It is immediate action to prevent the further use or distribution of non-conforming material. Containment usually consists of identifying the status of all affected material and quarantining non-conforming material to prevent further use (typically for a part or material) or distribution (typically for finished products). The containment action can be taken at the supplier end, sub-supplier end, organization, warehouse, transit warehouse, customer end, dealer end etc.

Example:

If you receive a customer complaint about a flash in the moulded component, the immediate containment action could include identifying and stopping the material at different stages like

- Material ready for despatch

- Material kept at the customer/supplier end

- The material in transit to the customer

- Material kept at the assembly area for final assembly

- Moulding process where flash is generated

Interim Action: are a “first aid” that protects the customer from the problem until we define the root cause and implement permanent corrective actions.

In some cases, the interim action may be the same as or similar to the emergency response action. However, an emergency response action is implemented with minimal supporting data. An interim provides more opportunity for investigation.

Example:

In the moulding process if the flash is coming in the moulded component. To control the process, maybe the process engineer can review the process parameter like temperature, time, pressure etc. and can make some modifications to them and after a few trials, if the flash is controlled, the revised process parameters can be frozen for the time being till we can validate the process and can find the root cause of the problem.

Read More: https://bit.ly/IshikawaDiagram

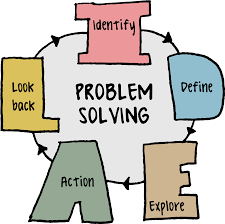

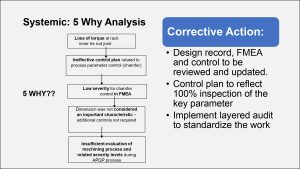

- Root Cause Analysis

As per Edward Deming, “85% of the reasons for failure to meet customer expectations are related to the deficiencies in the system and processes … rather than the employees.” Identify all applicable causes that could explain why the problem has occurred in terms of occurrence, outflow and systemic failure. Following are the key problem-solving tools:

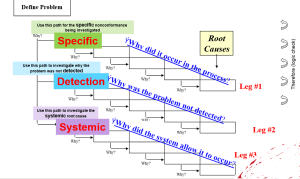

- 3 Layered 5 Why Analysis (3L5Y)

- Ishikawa (Fishbone) Diagram

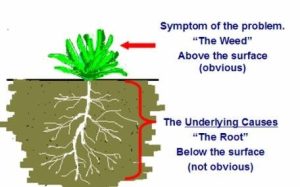

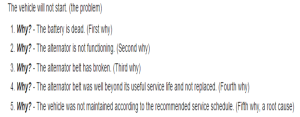

3 Layered 5 Why Analysis (3L5Y):

Occurrence leg– Why did this situation occur? Repeat five times, ensuring that each why points back to the previous answer.

Detection leg – Why was this situation overlooked? This leg examines why existing quality control procedures failed, allowing organizations to address this area of the process as well.

Systemic leg – Why did the systems in place permit the error to occur? This leg looks at the larger perspective for conditions that made errors possible.

How many WHY’s should you ask?

- Ask “Why” until the root cause is uncovered

- Maybe more than 5 Whys or less than 5 Whys

- If you don’t ask enough “Whys”, you may end up correcting a “symptom” and not “root cause”

- A root cause is usually a process, policy, design, or person.

- There can be more than one root cause

- Human error is an inadequate “Root Cause”

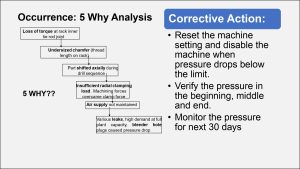

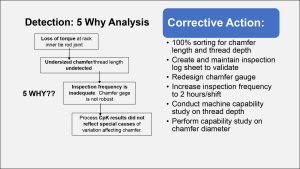

Example: 5Why Analysis:

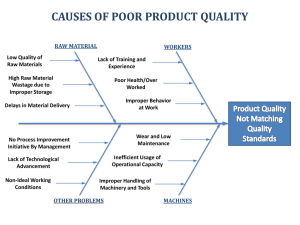

Ishikawa Diagram (Fish Bone Diagram):

Ishikawa Diagram (Fish Bone Diagram):

The Ishikawa diagram was developed by Kaoru Ishikawa during the 1960s and focuses on the multiple root causes for one quality issue. Each root cause or reason for bad quality is added to the diagram and grouped into categories to identify and classify these causes. The result looks like a fishbone, hence its name. The contour of the fish is optional. There are multiple causes.

- Primary Cause à leads directly to the effect

- Secondary Cause à leads to primary but does not directly cause and effect

- Implementation of Corrective Action

Purpose of Correction Action:

- To prevent recurrence

- Streamline workflow

- Identify cost-effective routes to correct errors

- Control or eliminate deficient practices

- Shall be appropriate to the effects of the nonconformities encountered

Steps for Correction Action Implementation:

- Risk assessment

- Corrective action for each root cause (Occurrence, Detection, Systemic)

- Feasible and within the time, Establishing responsibilities

- Customer approval, where needed

- Effective communication to all the relevant stakeholders

- Use of customer prescribed formats and methodology

Corrective Action on Occurrence:

Corrective Action on Detection:

Corrective Action on Systemic Failure:

Read More: https://bit.ly/CorrectiveActionStep5

- Effectiveness Evaluation

Quality pioneer W. Edwards Deming introduced the Plan-Do-Study-Act (PDSA) cycle as a planning, implementation, and continuous improvement tool.

Once the organization implements the Correction and Corrective Actions (Do), as per the PDCA cycle, the next logical and important step is t0 verify their effectiveness (Check).

13 Verification Steps:

- Whether Actually implemented: The above corrective actions are implemented or only on the paper (go to Gemba and check like many government projects like roads)?

- Whether Practical to implement: Whether proposed corrective action is practical to implement or not (Segregation done at customer/supplier end but both are not in the country or there is no moulding machine of that capacity in the organization)?

- Whether Communicated: All the stakeholders like operator, engineer, supervisor, supplier, customer etc. are communicated about the action plan (Like many companies, the action plan is made on the computer and shared with the customer as a similar type of problems have repeated many times)?

- Whether Resources provided: The desired resources are provided to the process owner like gauges, fixture, tooling, training, measuring instrument etc. (The new fixture is indented but still struck with the Purchase process for approval)?

- Whether Timeline defined: Any timeline is defined for its implementation (the new moulding fixture will be procured but by when!!)?

- Whether the Quantity in the process identified: How much quantity is in the process which needs to be consumed before the implementation will start or to be scrapped (Approximately 1000 pieces are at supplier end, 2500 at organization end, 1000 in the transit warehouse and 500 at the customer end. How to handle this material)?

- Whether Documents updated: All the relevant documents like PFC, PFMEA, Control Plan, SOP, Supplier PPAP etc. are reviewed and updated as per the action plan

- Whether Validation is done: The process and product to be validated after implementation of the proposed action plan. If yes, whether it is meeting the requirement

- How are Identification and Traceability defined: The product manufactured after the implementation of the corrective action is identified and their traceability is ensured while shipping it to the customer (old material and the material after modification)

- Whether Customer Feedback is taken: Any feedback is taken from the customer about the effectiveness of the proposed corrective action and are they satisfied?

- Whether Effectiveness Verified over a timeline: Do we have a process to see the effectiveness of the implemented action plan for a certain timeline or quantity?

- Effectiveness of Internal Audit Process: Whether the System audit, Manufacturing Process audit, Product audit, Layered audit is in place to verify the effectiveness of the action plan?

- Involvement of Top Management: If the top management is communicated about the effective implementation of the corrective actions and resultant cost incurred?

Read More: https://bit.ly/Step5EffectivenessImplementation

- Horizontal Deployment (Yokoten: Japanese)

The horizontal deployment (Yokoten) is not only about the best results and successes. It’s crucial that this sharing and peer-to-peer learning includes both successes and failures. The formal practice of sharing the learning from failure makes it less likely we hide failures.

Systemic:

Based on the systemic analysis, the root cause is identified and actions are implemented but whether all the other possible failures are considered or not Example: The root cause for the relay failure was dust and some actions are planned but dust can also impact other electronic components like semiconductor, resistor, capacitor etc. Have we deployed horizontal actions for other possible failures too?

Man:

On the job training provided to the operator in one final inspection line can be duplicated for remaining lines too (Example: QR Code wrongly identified in the final packing)

Machine:

- Fixture implemented in one machine can be implemented in other machines too where similar kind of problem can come (Example: PP moulding – Cooling Fixture)

Material:

To fulfil the End of the Life (EOL) requirement, action implemented on one type of material can be implemented on other variants too (Example: Lead-Free Wiring harness for all types of electrical fitting)

Method:

For the synchronous flow of the material, the process flow can be reviewed and changed for one product line. Similar process flow can be implemented for other product lines too (Example: In-process material is going out of the factory for outsourcing process 2 times (Painting and Sandblasting. The sequence can be changed so that both the processes can happen together).

Read More: https://bit.ly/HorizontalDeployment

Documentation, Lesson Learned and Promotion of Awareness:

As per the PDCA cycle, once the organization implement the Correction and Corrective Actions (Do), verified their effectiveness (Check) and horizontally deployed, the last logical step is to ensure that all the relevant documents are reviewed, updated and communicated to all the stakeholders.

Documents reviewed and updated like Drawing, Process Flow Chart, FMEA, Control Plan, SOP, OPL-One Point Lesson, Skill Matrix, Machine History card, Supplier PPAP, procedures, Internal audit results (System, Process, Product, Layered), Management review output etc.

Lessons Learned

- What information should be shared with other plants, departments, products, processes, suppliers?

- Consider similar/same products, processes, and equipment

- Lesson learned can be documented centrally and can be accessed easily by interested parties

Lessons Learned examples:

- Component mixing (Different Hardness) in heat treatment and similar can happen in the incoming inspection (steel bar of different grade but same diameter)

Read More: https://bit.ly/DocumentationCA

Industry Challenges:

- How often all the seven steps of the problem-solving technique are followed?

- How often CFT approach is used for problem-solving techniques?

- How often the tea is competent in problem-solving techniques?

References:

IATF 16949: 2016

ISO 9001: 2015

ISO 9000: 2015

OEM Supplier Manual

CQI 20: Aug 2018, 2nd Edition (Effective Problem-Solving Guide)

Industry Experts

This is the 149th article of this Quality Management series. Every weekend, you will find useful information that will make your Management System journey Productive. Please share it with your colleagues too.

In the words of Albert Einstein, “The important thing is never to stop questioning.” I invite you to ask anything about the above subject. Questions and answers are the lifeblood of learning, and we are all learning. I will answer all questions to the best of my ability and promise to keep personal information confidential.

Your genuine feedback and response are extremely valuable. Please suggest topics for the coming weeks.

Recent Comments