“Arise, Awake and Stop not until the goal is reached.” – Swami Vivekananda

Introduction

A single brain sometimes is not capable of taking critical decisions alone. An individual needs the support and guidance of others to come out with an effective solution. When individuals come together on a common platform with a common objective of accomplishing a task, a team is formed. Ideally, the team members should be from a common background and have a common goal to ensure maximum compatibility. The team members must complement each other and work in close coordination as a single unit to deliver their best.

Read More: https://bit.ly/KaizenMasaakiImai

Objective

A QC Circle is a small group consisting of first-line employees who continually control and improve the quality of their network, products and services. These small groups:

Operate autonomously,

Operate autonomously,

Utilize quality control concepts and techniques and other improvement tools

Tap members’ creativity

Promote self and mutual development

Once you read this blog, you will understand the true meaning of Quality Circle, how to implement it at your workplace successfully, the goal of Quality Circle, if QCC is effective, why it important and the possible benefits.

Read More: https://bit.ly/DOJOCentre

Definition:

Competence (ISO 9000: 2015, Cl 3.10.4): Ability to apply knowledge and skills to achieve intended results

Skill (ISO 30401: 2018, Cl 3.30): Learned capacity to perform a task to a specified expectation

Knowledge (ISO 30401: 2018, Cl 3.25): Human or organizational asset enabling effective decisions and actions in the context

Read More: https://bit.ly/5SSteps

Detailed Information

What is Quality Circle?

The Quality Circle is defined as a small group that voluntarily performs quality control activities within the shop where its members work. The small group carries out its work and continues as part of the companywide program of quality control, self-development, mutual development and improvement within the workshop.

Quality Circles were started in 1962 under JUSE (Union of Japanese Scientists and Engineers) auspices to build a cheerful and meaningful place of work and not for productivity and quality control! The QCC activities are voluntary and management should not force them on employees.

Read More: https://bit.ly/ROI-Training

What is the Purpose of Quality Circle?

– Develop members’ capabilities and achieve self-actualization

– Make the workplace more pleasant, vital and satisfying

– Improve customers satisfaction

– Contribute to society

The ultimate goal for a company is to make profits. To achieve it, the role of the cross-functional team is to focus on achieving QCD targets (Quality, Cost, Delivery). Without achieving these goals, the company will be left behind in competition because of inferior quality, erosion of profit due to high cost, and delay in delivery of the product to the customer. If the above three goals are achieved (QCD), profits will follow. Some of the possible outcomes for implementing QCC include

The ultimate goal for a company is to make profits. To achieve it, the role of the cross-functional team is to focus on achieving QCD targets (Quality, Cost, Delivery). Without achieving these goals, the company will be left behind in competition because of inferior quality, erosion of profit due to high cost, and delay in delivery of the product to the customer. If the above three goals are achieved (QCD), profits will follow. Some of the possible outcomes for implementing QCC include

- Achieve Maximum quality with maximum efficiency

- Maintain minimum inventory

- Eliminate hard work

- Maintain a questioning and open-minded attitude for constant improvement based on teamwork and cooperation

Read More: https://bit.ly/TrainerCompetency

How to Effectively Implement Quality Circle?

Like virtually any planned organizational change effort, quality circles go through a series of stages in their growth. Each phase contains its key activities as well as its threats to the program. Quality Circle projects provide better results when combined with Lean Manufacturing and TQM best practices.

Guidelines for Quality Circles Success

Once the Quality Circles are initiated in any organization, it is the responsibility of the top management to nurture them and pay attention to all relevant aspects related to the QC project.

The QC member should attend the meeting regularly, and punctually, and work in groups in the desired manner.

The QC member should attend the meeting regularly, and punctually, and work in groups in the desired manner.- Circle members should participate actively in the discussions and learn the techniques and new things taught to them.

- Training on 7 QC tools and kaizen must be given to all circle members.

-

- QC circles are formed with 4 to 6 members.

- The circle must select the leader among its members.

- A circle must have one facilitator and QC administrator who guide and support QC projects.

- Identify Quality Circlethemes and select a project based on priority.

- The Quality Circle meeting’s discussion points must be maintained in a record book and should be verified by the coordinator in the organization for correction and effectiveness.

- Circle follows the agenda without wasting time and listening to others while putting their points of view and suggestions.

- Quality circle members must maintain proper records of their activities.

Read More: https://bit.ly/CompetencyMapping1

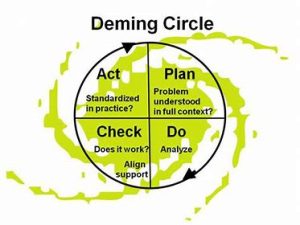

Quality Circle Problem Solving Steps

- Defining the Problem: Reduce the rejection from 500 ppm to 100 ppm

- Analyzing the Problem: Why rejection is so high

- Identifying the Cause: Possible causes of high rejection

- Finding out the Root Cause: The root cause of each possible reason

- Data Analysis on Root Cause: Analysing the data of the identified causes

- Developing Solution: Possible solution to reduce the rejection

- Foreseeing Possible Resistance: Possible challenges: cost, time, approval

- The trial, Implement and Checking Performance: Action to reduce the ppm

- Regular Implementation: Standardize documentation, training, etc.

- Follow–up / Review: Review the effectiveness of the action & change

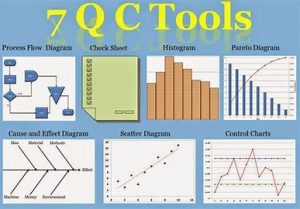

The most common QC tools and techniques used in QC Circle projects to analyze the problem, discover the root causes and helps to implement effective countermeasures are: 7 QC Tools

Check sheet

Check sheet- Fishbone diagram or Cause and effect diagram

- Pareto chart

- Control Chart

- Histogram or Frequency distribution chart

- Stratification of data

- Scatter diagram

There are some other potential quality tools used in quality circles techniques to analyze and solve quality problems effectively:

- Process flow diagram

- Bar graphs or charts

- Process mapping tools

- Run Chart

- Why-Why Analysis

Read More: https://bit.ly/Kirkpatrick4LevelModel

Who Should Participate in Quality Circle?

EVERYONE

If a department is starting a Quality Circle project, managers and all other employees should be included. If anyone is left out, this could lead to confusion or it will give the message to the employees that it is not their ownership. When people see their superiors taking QCC seriously by participating in it, they’ll be more likely to take it seriously, too.

Some people may play a bigger role in QCC than others, which is fine. There might be QCC coordinators who are in charge of installing and maintaining QCC, keeping track of assigned tasks, or introducing new department members to the QCC. QCC might initially take place as an event, but ideally, it becomes a part of daily work for everyone.

Read More: https://bit.ly/TraningNeedIdentification

If QCC is Expensive to Implement?

Business leaders considering using QCC may wonder if it is expensive to implement. Generally, it’s not. There may be an up-front investment and some time does need to be spent on training, which takes up employees’ and management’s time. In the long run, though, QCC makes processes run more smoothly, improves productivity, reduces wastages, and creates a better work environment and those things usually save businesses money.

Read More: https://bit.ly/CompetencyRequirement

Benefits of QCC

The outstanding feature of the Quality Circle concept (small group activity) is that the problems are thought of and dealt with by the workers albeit with management blessings and the workers arrive at a successful solution yielding improved productivity and quality control.

Some of the Key Benefits include

Some of the Key Benefits include

- Enhancement in sense of teamwork

- Communication between workers and management improves

- Improvement in the morale of the team

- Acquire new skills and knowledge

- Higher quality

- Increased productivity

- Greater employee satisfaction

- A safer work environment

Read More: https://bit.ly/EmployeeSatisfaction1

Industry Challenges:

- How often the results achieved by the QCC team is sustainable?

- How often the output of any QCC project is the result of the cross-functional team working for a couple of months, rather than results achieved through any other means?

- How often the real meaning and purpose of QCC is inculcated and followed in the organization?

- How often the awards given in any quality circle competition is based on the presentation (acting in front of the judges!) rather than actual work on the shop floor?

Read More: https://bit.ly/DifferenceCoachingMentoring

References:

ISO 9001: 2015

ISO 9002: 2016

ISO 9004: 2018

IATF 16949: 2016

Industry Experts

This is the 174th article of this Quality Management series. Every weekend, you will find useful information that will make your Management System journey Productive. Please share it with your colleagues too.

In the words of Albert Einstein, “The important thing is never to stop questioning.” I invite you to ask anything about the above subject. Questions and answers are the lifeblood of learning, and we are all learning. I will answer all questions to the best of my ability and promise to keep personal information confidential.

Your genuine feedback and response are extremely valuable. Please suggest topics for the coming weeks.

Leave a Reply

You must be logged in to post a comment.