“A man who does not plan long ahead will find trouble at his door.” ― Confucius

Introduction

During new year’s eve or during any festival, we take some personal pledges like I will lose weight, I will join the gym, I will control my hours on social media, I will avoid smoking and many more things. But after a couple of weeks and months, the majority of us are back to square one, even though we started very well. The key reason is the excitement of following the herd mentality and secondly not having any system to ensure that whatever we are committing, how we are going to sustain it.

Read More: https://bit.ly/QualityCircle

Objective

The PDCA Cycle and the SDCA Cycle are two structured thinking methodologies that have the same common approach: acting on a problem or an opportunity. While the PDCA Cycle seeks to solve a problem as efficiently as possible, the SDCA Cycle seeks to keep the process running with the assurance that this problem will not recur/opportunity will be encashed.

The article explains the relationship/differences between the SDCA and the PDCA cycle. These two cycles are implemented simultaneously or in a sequence to sustain and improve the processes in the organization. These are the important methodologies that are used in industries to improvise the systems of the organization to get better growth.

Once you read this blog, you will understand the key difference/relationship between PDCA and SDCA, how to implement it at your workplace successfully, why it is important and the possible benefits.

Read More: https://bit.ly/DOJOCentre

Definition:

Competence (ISO 9000: 2015, Cl 3.10.4): Ability to apply knowledge and skills to achieve intended results

Skill (ISO 30401: 2018, Cl 3.30): Learned capacity to perform a task to a specified expectation

Knowledge (ISO 30401: 2018, Cl 3.25): Human or organizational asset enabling effective decisions and actions in the context

Read More: https://bit.ly/5SSteps

Detailed Information

Read More: https://bit.ly/KaizenMasaakiImai

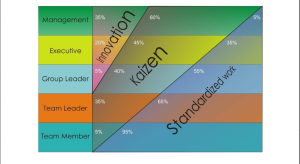

There are two important roles of leaders in every organization. The first role is to run the day-to-day business smoothly and the second role is to work on strategic goals to achieve the organization’s vision. The first role is called Daily Management or Nichijo Kanri and the second role is called Policy Deployment or Hoshin Kanri. Both originated in Japan and adapted across the world.

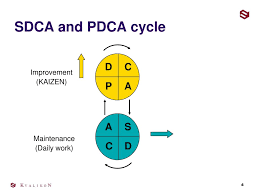

Hoshin Kanri symbolizes the PDCA (Plan-Do-Check-Act) cycle in the KAIZEN perspective, while Nichijo Gemba Kanri represents the SDCA (Standardize-Do-Check-Act) cycle. Nichijo Gemba Kanri (SDCA) is, therefore, necessary for Hoshin Kanri (PDCA).

Hoshin Kanri symbolizes the PDCA (Plan-Do-Check-Act) cycle in the KAIZEN perspective, while Nichijo Gemba Kanri represents the SDCA (Standardize-Do-Check-Act) cycle. Nichijo Gemba Kanri (SDCA) is, therefore, necessary for Hoshin Kanri (PDCA).

In other words, Daily Management (SDCA) is focusing on short-term and Policy Deployment (PDCA) in long term. They complement each other and we cannot ignore either of them. Lack of Daily Management (SDCA) causes firefighting and Lack of Policy deployment (PDCA) cause stagnant business growth.

Read More: https://bit.ly/DailyWorkManagement

What is PDCA

The PDCA cycle (circle) is a crucial part of the continuous improvement philosophy. It is also known as the Deming Wheel, Deming Cycle, or Shewhart Cycle in practice.

PDCA is utilized in all components and requirements of continuous improvement. Deming suggests that PDCA should be a way of performing continuous improvement not only in business but also in all aspects of one’s daily life.

PDCA is utilized in all components and requirements of continuous improvement. Deming suggests that PDCA should be a way of performing continuous improvement not only in business but also in all aspects of one’s daily life.

Deming presents PDCA as a tool for teams and organizations to increase confidence, and acceptance, and prosperity in the competition.

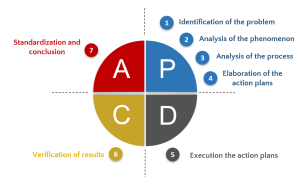

- Plan – characterizing the problem, and then working on the plan for the implementation.

- Do – implementing planned solutions and changes.

- Check – checking, whether assumed earlier results are being obtained, at the permanent observation of crucial processes, whether together with applying solutions new problems do not appear.

- Act – implementing changes.

Read More: https://bit.ly/EmployeeSatisfaction1

What is SDCA

“Everything deteriorates over time; there is no stable condition that can be maintained. The only solution is to improve constantly”: Mike Rother

The process of stabilization is called the SDCA cycle (standardize – make – check – act). SDCA is about ensuring, via audit, that standardized work is being adhered to and is sufficient. A process needs to be stabilized through standardization to make it more measurable, predictable, and controllable. Improvements cannot and must not be made to a process unless it is stable.

While doing the root cause analysis, generally, the following are the 3 key root causes for any problem

- Lack of a Standard

- Not following a Standard

- Wrong Standard

So, the similarity in all the above three root causes is Standard!

Read More: https://bit.ly/CompetencyMapping1

SDCA is a methodology to sustain improvements by:

Standardize: In this stage product need to be defined as the goal to be achieved with considering the limits of acceptance. We can define the critical product characteristics and define operational control indicators. The Standard operating procedure(SOP) is also defined with the mapping of processes and those who are responsible for executing the SOP.

Standardize: In this stage product need to be defined as the goal to be achieved with considering the limits of acceptance. We can define the critical product characteristics and define operational control indicators. The Standard operating procedure(SOP) is also defined with the mapping of processes and those who are responsible for executing the SOP.- Do: Implement standards. The objective is to comply with the established procedures, it is necessary the team training and the provision of the procedures.

- Check: Verify the actual work with standards. Any deviation from the standard should prompt the following 3 questions: Did the deviation occur because no standard exists? Did the deviation occur because the standard is inadequate? Did the deviation occur because the standard was ignored?

- Act: Review and assess any variation in standard. The goal of this step is to correct problems that were not previously occurred For example the results were not as expected, the team was unable to understand the goal. And inadequate working conditions.

“Where there is no standard, there can be no kaizen.” – Taiichi Ohno

Example: The organization may have implemented TPM (Total Productive Maintenance) in their organization and won the prestigious TPM Excellence award. Now, if the organization does not continue to work on their machine every single day with tools like CLIT: Cleaning, Lubrication, Inspection, Tightening, 5S, Standard Operating Procedures (SOP), Control charts, Statistical tools, poka-Yoke etc., the performance of the machine and related processes will start deteriorating.

Read More: https://bit.ly/ROI-Training

Key Difference between PDCA and SDCA

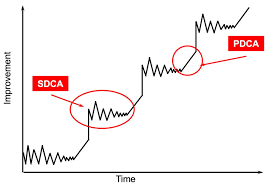

As an example, think about when you climb a ladder: to go to the next step you have to rest your feet on the stable surface of the previous step, correct?

The relationship between these two methodologies is the same! To achieve greater performance and competitive advantage through the use of the PDCA Cycle, a company must first support its new goals and objectives based on its current situation and for this, the SDCA Cycle is used.

In industry, if we are working on the improvement of any section of the organization such as productivity, and we set a target and improve the processes and enhanced productivity, and we improve it again and again by applying the PDCA methodology. Using the PDCA methodology, we must have identified some root causes and also acted on them. But by working with the PDCA methodology, we had to ensure that we had standardized the processes and that the processes do not go in the previous situation.

In industry, if we are working on the improvement of any section of the organization such as productivity, and we set a target and improve the processes and enhanced productivity, and we improve it again and again by applying the PDCA methodology. Using the PDCA methodology, we must have identified some root causes and also acted on them. But by working with the PDCA methodology, we had to ensure that we had standardized the processes and that the processes do not go in the previous situation.

If we do not standardize and sustain the process that had been improved by us then the previous situation will get reflected in the present and our efforts will be considered a waste.

Read More: https://bit.ly/Kirkpatrick4LevelModel

Hence the SDCA works simultaneously with the PDCA cycle to standardize the processes.

To improve any part of the system, First, the SDCA cycle is used to sustain the processes that are implemented in the system. And after that, the PDCA cycle is implemented for the improvement of the system and SDCA follows again and this cycle continues.

Read More: https://bit.ly/TrainerCompetency

How important is the use of the PDCA Cycle and the SDCA Cycle?

Regardless of whether a company separates them by name or not, understanding the importance of using these methods in parallel is crucial, as it is not enough to only achieve better results, the organization must also keep them afterward! It is only in this way that the actions of correction, prevention and improvement actually perpetuate themselves over time.

Benefits of PDCA and SDCA

- The possibility of losses reduces.

- Sustaining improvements becomes easier with SDCA.

- Wastage of time is reduced as standards are set for all activities, and there is a clear indication of what is to be done and how it is to be done.

- Helps raise the bar for improvement standards.

- Enable measurement of the level of implementation of improvements and standards.

- Helps to sustain lean gains and develop a lean culture

Basically, SDCA helps to ensure that the processes are sustainable. And the PDCA cycle helps to enhance the performance of the system. So, it is important for the organization to use the SDCA cycle as well as the PDCA cycle simultaneously.

Read More: https://bit.ly/TraningNeedIdentification

Industry Challenges:

- How often PDCA and SDCA approach is understood in the industry?

- How often Standardization (SDCA) is given importance in the organization for the sustained growth

Read More: https://bit.ly/DifferenceCoachingMentoring

References:

ISO 9001: 2015

ISO 9002: 2016

ISO 9004: 2018

IATF 16949: 2016

Industry Experts

This is the 176th article of this Quality Management series. Every weekend, you will find useful information that will make your Management System journey Productive. Please share it with your colleagues too.

In the words of Albert Einstein, “The important thing is never to stop questioning.” I invite you to ask anything about the above subject. Questions and answers are the lifeblood of learning, and we are all learning. I will answer all questions to the best of my ability and promise to keep personal information confidential.

Your genuine feedback and response are extremely valuable. Please suggest topics for the coming weeks.

Leave a Reply

You must be logged in to post a comment.