“The only people who see the whole picture are the ones who step outside the frame.”

― Salman Rushdie”

Introduction

At work and in life, problems can crop up. Even if you don’t know how to fix the problem at first, you can think about how the problem happened in the first place. Then you can keep calm and use logic to find some good solutions.

Life will always have problems to overcome, from figuring out why your phone isn’t working to dealing with a tricky customer at work.

Employers want to know how you deal with problems because they want you to see a problem as a challenge that can be overcome if you deal with it logically.

Objective

FTA or Fault Tree Analysis is a simple, down-to-earth proactive technique to design reliability into products. This technique also helps to redesign the existing processes or to carry out problem-solving related to existing or potential problems. It relies on a ‘systematic and logical approach through the development of problem tree’. FTA may utilize historic data to get a quantitative estimate of the problem.

FTA is a failure analysis in which an undesired state of a system is analyzed using Boolean logic to combine a series of lower-level events. This analysis method is often used in the field of safety engineering to quantitatively determine the probability of a safety hazard.

Definitions (IATF 16949: 2016)

Fault Tree Analysis (FTA): Deductive failure analysis methodology in which an undesired state of a system is analyzed; fault tree analysis maps the relationship between faults, subsystems and redundant design elements by creating a logic diagram of the overall system.

Detailed Information

Fault tree analysis (FTA) is a top-down, deductive failure analysis in which an undesired state of a system is analyzed using Boolean logic to combine a series of lower-level events.

Prevention is always better than cure!

FTA was originally developed in the 1960s during the development of Intercontinental Ballistic Missiles (ICBM). Later it was utilized in the `Minuteman’ (1962) project in USA and Bell Telephone Laboratories (missile launching control system).

FTA Timeline:

- Design Phase

- FTA should start early in the program

- The goal is to influence design early before changes are too costly

- Update the analysis as the design progresses

- Operations Phase

- FTA during operations for root cause analysis

- Find and solve problems (anomalies) in real-time

What is FTA?

- A common tool using graphics and statistics to analyze an event and predict how and how often it will fail

- Used in engineering and business to aid process and system development

Why do we use FTA?

- Very easy to understand

- An effective way to diagram problems in a system

- Helps to organize possible causes of a problem in the system

FTA Analysis – 5 Steps:

- Define the undesired event to study

- Obtain an understanding of the system

- Construct the fault tree

- Evaluate the fault tree

- Control the hazards identified

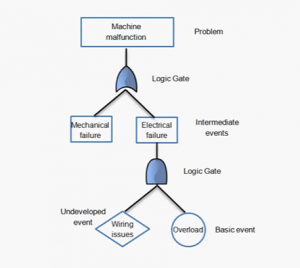

Example:

Is FTA a tool for you?

- Does your company have problems with your system or process flow?

- Does your system work under the worst-case scenario?

- Do external forces affect your system?

How does it work?

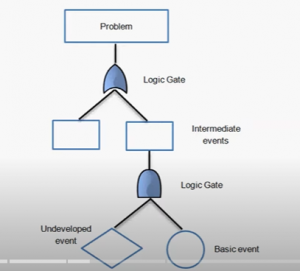

- Uses a variety of gates and events to explain the system

- Uses a top-down approach to its logic

- The end result is at the top of the tree and what leads to that result follows under it

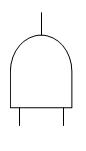

AND Gate:

- One of the main gates used

- The output above will occur if the two events below both occur

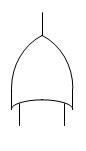

OR Gate:

- The second main gate used

- The output above will occur if either of one or more events happens below

Three Main Events:

- Primary Event

- Intermediate Event

- Expanded Event

Primary Events:

- Made up of basic, undeveloped, and external events

- A time in the event where the process or system might fail

Intermediate Events:

- A combination of multiple different faults

- Shown by rectangles in the fault tree

- Sometimes linked by and/or gates

Expanded Events:

- The complex event that needs another fault tree to explain

- The fault tree for the expanded event is not directly shown in the current fault tree

- Shown by a triangle on the fault tree

Boolean algebra is the branch of algebra in which the values of the variables are the truth values true and false, usually denoted 1 and 0, respectively.

Basic Mathematical foundation:

Events in a fault tree are associated with statistical probabilities or Poisson-Exponentially distributed constant rates.

For example, component failures may typically occur at some constant failure rate λ (a constant hazard function). In this simplest case, failure probability depends on the rate λ and the exposure time t:

P = 1 – exp(-λt)

where:

P ≈ λt if λt < 0.001

Strengths of FTA Model:

- Visual method: cause and effect relationship

- Easy to learn and follow

- Models’ complex system relationships in an understandable manner

- Probability model

- Scientifically sound: Boolean Algebra

- Proven technique

Comparison with other Analytical Methods:

| S.No. | FTA | FMEA |

| 1 | Deductive, Top-Down method | Inductive, Bottom-Up Analysis method |

| 2 | analyzing the effects of initiating faults and events on a complex system | analyzing the effects of a single component or function failures on equipment or subsystems |

| 3 | good at showing how resistant a system is to single or multiple initiating faults | not good at examining multiple failures or their effects at a system level. |

| 4 | considers external events | Does not consider external events |

| 5 | not good at finding all possible initiating faults. | good at exhaustively cataloguing initiating faults, and identifying their local effects |

Summary:

- An important tool

- Simple to use

- Graphics make it easy to understand

- Each event is displayed by a unique shape

- Helps to prevent and correct errors in the system

Present Challenges

- Whether manufacturing industries are aware of this tool?

- If yes, how often this tool is used during the design and operation phase?

References:

IATF 16949: 2016

ISO 9001: 2015

Industry Experts

This is the 139th article of this Quality Management series. Every weekend, you will find useful information that will make your Management System journey Productive. Please share it with your colleagues too.

In the words of Albert Einstein, “The important thing is never to stop questioning.” I invite you to ask anything about the above subject. Questions and answers are the lifeblood of learning, and we are all learning. I will answer all questions to the best of my ability and promise to keep personal information confidential.

Your genuine feedback and response are extremely valuable. Please suggest topics for the coming weeks.

Leave a Reply

You must be logged in to post a comment.