The difference between hearing and listening is paying attention: Ruth Messinger

Introduction

There are 3 key rules related to effective documentation. They are

- Immediate

- Accurate & believable

- Agreed upon

Once done, it ensures efficiency, consistency, and peace of mind for anyone involved.

Objective

Failure Mode and Effects Analysis (FMEA) is a well-established method in the manufacturing industry, commonly applied to optimize product/process reliability and cost. It requires cross-functional teams to identify and evaluate the product/process functions, to continuously improve them to reduce risks. The FMEA is a living document and is re-evaluated many times during its lifecycle.

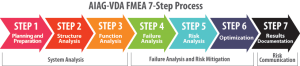

The purpose of the Results Documentation (Step 7, as per FMEA Handbook: AIAG & VDA 1st Edition 2019) is aimed at facilitating complete understanding about establishing the content of the documentation, documenting the effectiveness of the actions taken and assessment of the risk after the action is taken, communicating the actions to reduce risk within the organization, customer, supplier and finally recording the risk analysis & risk reduction.

Detailed Information

FMEA (Failure Mode & Effect Analysis) is a team-oriented, systematic, qualitative and analytical method to identify, analyse and mitigate the technical risks related to the ‘product and manufacturing process design.

The FMEA is the ‘Before the Event’ and not the ‘After the Event’ exercise.

The effectiveness of the FMEA can be gauged from the improvement in COQ (Cost of Quality) and COPQ (Cost of Poor Quality)

7 Step Process:

- Planning & Preparation: Objectives, Project identification, plan boundaries

- Structure Analysis: Process Item, Process step, process work element

- Function Analysis: Intended Function/Requirement

- Failure Analysis: Failure Effect, Failure Mode, Failure Cause

- Risk Analysis: Prevention and Detection Control, Severity/Occurrence/Detection

- Optimization: Recommended Actions, Responsibility, target date, revised S, O, D

- Result Documentation

Results Documentation (Step 7: FMEA 1st Edition)

There are 5 key objectives through which we can clearly understand the Results Documentation

- Communication of the results and conclusion of the analysis

- Establish: Content of the documentation

- Documentation: Effectiveness of the actions taken and assessment of the risk after action taken

- Communication: Actions to reduce risk within organization, customer, supplier

- Record: Risk analysis, risk reduction

FMEA Report:

The content of the FMEA report should fulfill the requirements of the organization, intended reader and the relevant stakeholders.

The analysis details and the intellectual property should remain safe and with the developing company

The content of the FMEA Report may include

- Final status compared to the original goals (Step 1: Planning and Preparation)

- InTent: Purpose of making FMEA?

- Timing: FMEA due date?

- Team: Cross Functional Team?

- Task: Scope of FMEA?

- Tool: How do we conduct the analysis?

- Summary of the scope of the analysis and identify what is new (Step 2: Structure Analysis)?

- Summary of how functions were developed (Step 3: Function Analysis).

- Summary of high-risk failures, Severity/Occurrence/Detection rating and Action Priority (Step 4: Failure Analysis)

- Summary of action planned/taken for the high-risk failures (Step 5: Risk Analysis)

- Commitment (Step 6: Optimization)

- Commitment and timing to close open actions

- Commitment to review and revise FMEA during mass production, Design change, corrective actions

3. Capture ‘Things Gone Wrong (TGR)’ for future FMEA analysis

Present Challenges

- How often the cross-functional team is clear about the requirements of steps 1 to 7 and plan and prepare themselves accordingly?

- How often the FMEA is reviewed and updated in case of any design change, corrective action, Things Gone Wrong?

References:

IATF 16949: 2016

FMEA Handbook (AIAG-VDA 1st Edition June 2019)

Industry Experts

This is the 128th article of this Quality Management series. Every weekend, you will find useful information that will make your Management System journey Productive. Please share it with your colleagues too.

In the words of Albert Einstein, “The important thing is never to stop questioning.” I invite you to ask anything about the above subject. Questions and answers are the lifeblood of learning, and we are all learning. I will answer all questions to the best of my ability and promise to keep personal information confidential.

Your genuine feedback and response are extremely valuable. Please suggest topics for the coming weeks.

Leave a Reply

You must be logged in to post a comment.