It is the teacher that makes the difference, not the classroom: Michael Morpurgo

Introduction

Cause and Effect refer to a relationship between two phenomena in which one phenomenon is the reason behind the other. For example, eating too much fast food without any physical activity leads to weight gain. Here eating without any physical activity is the “cause” and weight gain is the “effect.” Another popular example is that of smoking and lung cancer, wherein smoking causes lung cancer (effect).

Objective

Failure Mode and Effects Analysis (FMEA) is a well-established method in the manufacturing industry, commonly applied to optimize product/process reliability and cost. It requires cross-functional teams to identify and evaluate the product/process functions, to continuously improve the product/process to reduce risks. The FMEA is a living document and is re-evaluated many times during its lifecycle.

The purpose of the Function Analysis (Step 3 as per FMEA Handbook: AIAG & VDA 1st Edition 2019) is aimed at facilitating complete understanding of the Product/Process by using Parameter (P) chart, Process Flow chart and Structure tree.

Detailed Information

FMEA (Failure Mode & Effect Analysis) is a team-oriented, systematic, qualitative and analytical method to identify, analyse and mitigate the technical risks related to the ‘product and manufacturing process design.

The FMEA is the ‘Before the Event’ and not the ‘After the Event’ exercise.

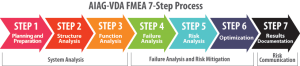

7 Step Process:

- Planning & Preparation: Objectives, Project identification, plan boundaries

- Structure Analysis: Process Item, Process step, process work element

- Function Analysis: Intended Function/Requirement

- Failure Analysis: Failure Effect, Failure Mode, Failure Cause

- Risk Analysis: Prevention and Detection Control, Severity/Occurrence/Detection

- Optimization: Recommended Actions, Responsibility, target date, revised S, O, D

- Result Documentation

Key Difference Between Function and Function Analysis (Step 3)

Function Analysis:

- Exploration of what the product should be doing in the Function Analysis step

- What should be executed in the general process (and each one of its activities) and how this functionality is facilitated.

- Using the Structure Analysis (step 2), each element is analyzed separately in terms of its function and corresponding requirements.

- The focus is on the question: ‘what does the thing that we want to analyze DO?’

- The results of the structural analysis are a crucial input for the functional analysis, as to how functions are correctly described from a technical point of view.

- The functional analysis is at the heart of any successful FMEA.

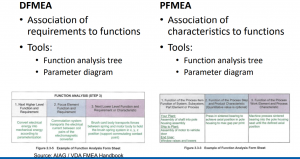

- Parameter diagrams (P-diagrams) are frequently used to describe the functions precisely.

The objectives of the functional analysis are:

- Detailed graphical representation of the function (visualization)

- Creation of a functional tree/network and a functional analysis form and P-diagram (DFMEA) or process flow chart (PFMEA)

- Detailed gradation of the external and internal customer functions and their requirements in the analysis

- Linking of the defined requirements and characteristics

- Practical cooperation of the development team

- Precise definition as the basis for the 4th step (the failure analysis)

Function:

It describes what the process item or process step (Item/System Element-DFMEA) is intended to do.

It also describes the relationship between the input and output of an item element to fulfill a task.

The description of the function should be clear.

- ‘Action Verb’ followed by ‘Noun’ to describe a ‘measurable function’

- The ‘function’ should be in the PRESENT TENSE (Deliver, Contain, Control)

- Example: Deliver Power, Contain Fluid, Control Speed, Drill Hole, Insert Pin

Requirement: As per ISO 9000: 2015, it is a need or expectation that a particular design, product or process aims to satisfy.

Requirements: Functional, Non-functional

5 Sources of Requirement:

- Legal Requirements (recycling, environmental)

- Industry norms and Standard (ISO 26262: Functional Safety)

- Customer requirements (drawing, technical specifications)

- Internal requirements (Packaging, Manufacturability)

- Product characteristics (Diameter, surface finish)

Functional Analysis:

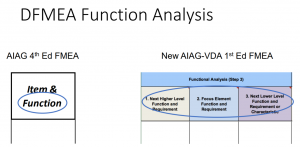

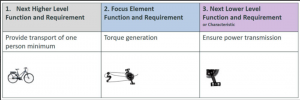

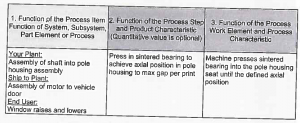

For DFMEA, functions and requirements are identified by the next higher level function (highest level of integration within the scope of analysis), focus element (item in focus), and next lower level function (the element that is next level down the structure from focus element).

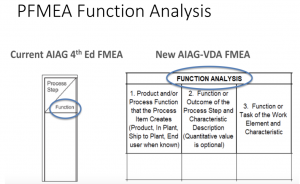

For PFMEA, functions and requirements are identified by the function of the process item system, the function of process step and product characteristic, and the function of the process work element and process characteristic.

Parameter Diagram (P Diagram): Characterize the behaviour of a system or component in the context of a single function. It focuses on the achievement of the function.

- Input (what you want to put in to get the desired results)

- Function (what you want to happen)

- Functional requirements (what you need to make the function happen)

- Control factors (what you can do to make it happen)

- Non-functional requirements (needed apart from functional requirements)

- Intended output (what you want from the system)

- Unintended outputs (what you do not want from the system)

- Noise factors (what interferes with achieving the results)

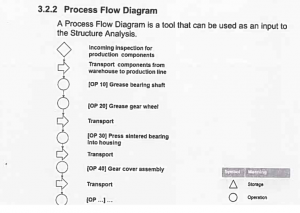

Process Flow Diagram:

It helps to define the process and provide the basis for the structure analysis.

Failure analysis is useful in finding, Failure Effect (FE), which is nothing but a negative function of the process, which can come out by listing the positive function of a function.

Summary:

Present Challenges

- How often the cross-functional team is clear about the requirements of step 3 and its difference with step 2?

- How often Parameter Diagram (P Diagram) and Structure Tree are prepared before analyzing step 2?

References:

IATF 16949: 2016

FMEA Handbook (AIAG-VDA 1st Edition June 2019)

FMEA 4th Edition (AIAG- 2008)

Industry Experts

This is the 126th article of this Quality Management series. Every weekend, you will find useful information that will make your Management System journey Productive. Please share it with your colleagues too.

In the words of Albert Einstein, “The important thing is never to stop questioning.” I invite you to ask anything about the above subject. Questions and answers are the lifeblood of learning, and we are all learning. I will answer all questions to the best of my ability and promise to keep personal information confidential.

Your genuine feedback and response are extremely valuable. Please suggest topics for the coming weeks.