The greatest waste in the world is the difference between what we are and what we could become: Ben Herbster

Introduction

What is the difference between Relation and Relationship? When we talk about ‘Relation’, primarily we are talking about the superficial association with another person. But when talk about ‘Relationship’, our intent is about the deep bond that we are having with another person.

Objective

The purpose of an FMEA process is to continuously improve the process to reduce risks. The FMEA is of course a living document and will be re-evaluated many times during its lifecycle.

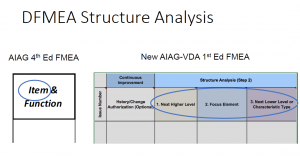

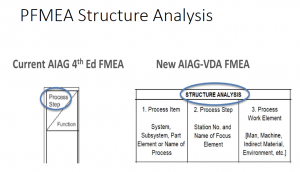

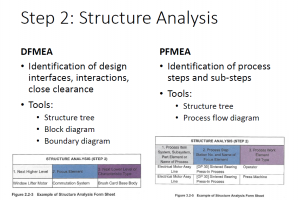

The purpose of the Structure Analysis (Step 2 as per FMEA Handbook: AIAG & VDA 1st Edition 2019) is aimed at facilitating complete understanding of the Product/Process by using block diagram, boundary diagram (DFMEA), process flow chart and structure tree (PFMEA).

Detailed Information

FMEA (Failure Mode & Effect Analysis) is a team-oriented, systematic, qualitative and analytical method to identify, analyze and mitigate the technical risks related to the ‘product and manufacturing process design.

The FMEA is the ‘Before the Event’ and not the ‘After the Event’ exercise.

7 Step Process:

- Planning & Preparation: Objectives, Project identification, plan boundaries

- Structure Analysis: Process Item, Process step, process work element

- Function Analysis: Intended Function/Requirement

- Failure Analysis: Failure Effect, Failure Mode, Failure Cause

- Risk Analysis: Prevention and Detection Control, Severity/Occurrence/Detection

- Optimization: Recommended Actions, Responsibility, target date, revised S, O, D

- Result Documentation

Key Difference Between Item/Process Steps and Structure Analysis (Step 2)

Structure Analysis:

- Structure analysis is aimed at facilitating a complete understanding of the Product/Process.

- It is used to identify and break down the Product/Process into sequential steps, interfaces and logistical elements.

- Input for the Functional Analysis (Step 3)

- Collaboration between customer and organization

- It uses the boundaries stipulated in the definition of scope done in step 1 to identify each stage, interface and logistical element in the process at hand.

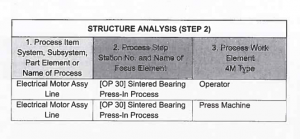

- It consists of three expanded columns whose purpose is to facilitate a thorough understanding of the process. Start with the Focus Element in the “middle column,” then identify the Process of which the Focus Element is a part and finally identify all Process Work Elements of the Focus Element.

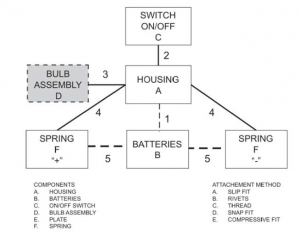

- In Design FMEA, structure analysis is used to identify and break down the FMEA scope into System, Subsystem and components parts for technical risk analysis by using a Block (Boundary) diagram.

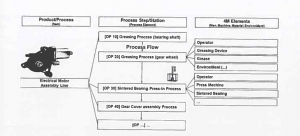

- In Process FMEA, structure analysis is used to identify and break down the FMEA scope of the manufacturing system into Process items, Process Steps and Process work elements by using Process Flow Chart and Structure Tree.

Block Diagram (Boundary):

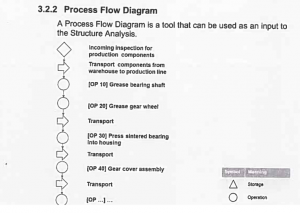

Process Flow Diagram:

It helps to define the process and provide the basis for the structure analysis.

Structure tree:

- It arranges the system elements hierarchically.

- Illustrates the dependencies via a structural connection.

- Pictorial structure: Relationship between

- Process Items (Main Process like Assembly)

- Process Steps (Different activities in the Assembly process)

- Process Work Elements (4M or 6M: Man, Machine, Material Method, Measurement, EnvironMent)

If process elements are missing from the structure analysis, they will also be missing from the Function analysis

Summary:

Present Challenges

- How often the cross-functional team is clear about the requirements of step 2 and its difference with step 3?

- How often Block Diagram and Structure Tree is prepared before analyzing step 2?

References:

IATF 16949: 2016

FMEA Handbook (AIAG-VDA 1st Edition June 2019)

FMEA 4th Edition (AIAG- 2008)

Industry Experts

This is the 125th article of this Quality Management series. Every weekend, you will find useful information that will make your Management System journey Productive. Please share it with your colleagues too.

In the words of Albert Einstein, “The important thing is never to stop questioning.” I invite you to ask anything about the above subject. Questions and answers are the lifeblood of learning, and we are all learning. I will answer all questions to the best of my ability and promise to keep personal information confidential.

Your genuine feedback and response are extremely valuable. Please suggest topics for the coming weeks.

Leave a Reply

You must be logged in to post a comment.