“Toleration has never been the cause of civil war. While on the contrary, persecution has covered the earth with blood and carnage.” – Voltaire

Introduction

Students aspire to get more than 95%. Patients want to control their blood pressure between 80 to 120. In the Share market, investors always want the prices to go higher and higher although there is a circuit breaker on both higher and lower sides. A middle-class person always has limited means to run the household.

Content: SPC: Unilateral Tolerance Capability Indices

- What is the Unilateral Tolerance?

- How do we calculate capability indices for Unilateral Tolerance?

- How to use it?

- Conclusion

Objective

Walter Shewhart and W Edward Deming have done tremendous work to understand the variation in the process and its causes through statistical studies (mean, range, UCL, LCL, Cp, Cpk, Pp, Ppk, p, np, c, u). Understanding these variations is important to improve quality, reduce cost and increase productivity (QCD).

In an organization, the designer decides both unilateral and bilateral tolerances. Each has its meaning and purpose. While plotting the control chart and calculating the Pp/Cp and Ppk/Cpk values, there are certain key differences.

Once you go through the article, you will understand the meaning of both unilateral & bilateral tolerances and how to calculate the Pp/Cp and Ppk/Cpk values.

Read More: http://bit.ly/VariableAttributeControlChart

Definition: SPC: AIAG Manual 2nd Edition

SPC (Statistical Process Control): It is a collection of statistical techniques intended to understand the behaviour of a process.

Process Capability: It is determined by the variation that comes from the common causes. It generally represents the best performance of the process itself. This is demonstrated when the process is being operated in a state of statistical control regardless of the specification.

Common Cause: Variations that are consistently acting on the process. Produce a stable and repeatable distribution over time (in a state of statistical control)

Special Cause (Assignable causes): Variations that affect only some part of the process output. Often intermittent and unpredictable.

Variable Chart: It explains the process data in terms of its process variation, piece-to-piece variation, and its process average.

Specification Limits are the targets set for the process/product by customer or market performance or internal target. In short, it is the intended result on the metric that is measured. They have discrete values and can be counted for recording and analysis.

Control Limits are the indicators of the variation in the performance of the process. It is the actual values that the process is operating on. It is the real-time value.

Read More: http://bit.ly/CommonSpecialCause

Detailed Information

Dr Walter Shewhart developed the first control chart in the 1920s to describe common and special causes for Detection (tolerates waste) and Prevention (avoid waste)

The key objective of implementing statistical techniques is to

The key objective of implementing statistical techniques is to

- Improve quality.

- Increase productivity.

- Reduce cost.

There is a fundamental law of nature that no two products or characteristics are exactly alike as processes contain many sources of variation. The differences may be immeasurably small or large, but they will always be there.

Read More: http://bit.ly/AttributeCharts

The statistical study is built on the strategy of prevention. Based on the statistical study, there can be 3 key types of variation in the process

Location (mean/central value)

Location (mean/central value)- Spread (width/span)

- Shape (Pattern of variation-skewed, asymmetrical etc.)

The key goal is to maintain the location to the target value with minimal variability.

Read More: https://bit.ly/StopLightControl

What is a Tolerance?

Tolerances on technical drawings communicate the amount of variation permitted from a target dimension. The allowable variation can be visualized as a zone surrounding the ideal surface of the part – what is called a “true profile.” For parts to be within tolerance, all points on the surface must fall inside this limit, known as a “tolerance zone.”

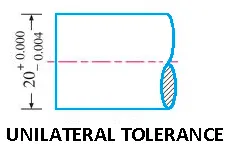

What is Unilateral Tolerance?

Unilateral tolerance is a type of unequally disposed tolerance where variation from the true profile is only permitted in one direction. Unilateral tolerance allows us to specify tolerances in a way that matches the thought process of our design.

Example: 5 +0.1 mm. Upper side: 5.1 mm, Lower Side: 5.0 mm

Example: 5 -0.1 mm. Upper side: 5.0 mm, Lower Side: 4.9 mm

Purpose of Unilateral Tolerance?

The reason for using unilateral tolerances is to shift the statistical variation of parts toward one end of the allowable range so that the parts fit better at Maximum Material Condition (MMC), creating better quality and longer-lasting assembly.

Read More: https://bit.ly/SPCControlChart

How to Calculate Cp and Cpk value for Unilateral Tolerance?

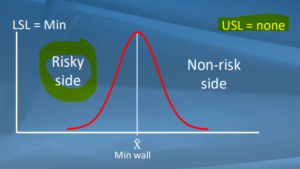

- Example: Shaft runout would have a maximum specification, not to be exceeded (Shaft runout cannot be more than 0.1 mm).

Example: The wall thickness should not be less than specification, not below the specifications (Wall thickness: Minimum 5 mm required)

Read More: http://bit.ly/SpecificationControlLimits

The formula for Cp:

Cp is a capability index. It compares the process capability to the maximum allowable variation as indicated by the tolerance. This index has no meaning for the Unilateral tolerance.

Cp is a capability index. It compares the process capability to the maximum allowable variation as indicated by the tolerance. This index has no meaning for the Unilateral tolerance.

Example:

- Lower Tolerance: Wall thickness: Minimum 5 mm required

- Higher Tolerance: Shaft runout cannot be more than 0.1 mm

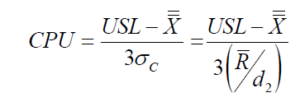

In the case of Unilateral tolerance, either USL or LSL is not applicable. Hence the formula (USL-LSL) can not be used. It means that in the case of Unilateral tolerance, Cp can NOT be calculated.

The formula for CpK (Lower and Upper):

Depending upon whether the lower or higher specification is applicable while calculating the CpK value, either CPL or CPU will be calculated.

Read More: http://bit.ly/DifferenceMeanMedianMode

What is Bilateral Tolerance?

Bilateral tolerance is the term used when the tolerance zone is distributed from the target value or true profile in both directions. Bilateral tolerances allow equal variation on each side of the target.

Example: 5+/- 0.1 mm. Upper side: 5.1 mm, Lower Side: 4.9 mm

Read More: https://bit.ly/SPCGoalpost

Conclusion:

The purpose of the SPC study is to understand the process variation. Bilateral profile tolerance means variation from the true profile is permitted equally in both directions. Unilateral profile tolerance means that variation from the true profile is permitted in one direction only.

The unilateral has a certain intended purpose as per design. While calculating the capability indices, Cp and Pp can not be calculated but CpK can be calculated either for the lower or higher side.

Read More: http://bit.ly/CommonSpecialCause

References:

IATF 16949 Standard

SPC AIAG Manual 2nd Edition

Industry Experts

This is the 216th article of this Quality Management series. Every weekend, you will find useful information that will make your Management System journey Productive. Please share it with your colleagues too.

In the words of Albert Einstein, “The important thing is never to stop questioning.” I invite you to ask anything about the above subject. Questions and answers are the lifeblood of learning, and we are all learning. I will answer all questions to the best of my ability and promise to keep personal information confidential.

Your genuine feedback and response are extremely valuable. Please suggest topics for the coming weeks.

Leave a Reply

You must be logged in to post a comment.