“Realize the difference between truth and opinion.” ― Unknown

Introduction

What is the difference between day and night? The Earth orbits the Sun once every 365 days and rotates about its axis once every 24 hours. Day and night are due to the Earth rotating on its axis, not its orbiting around the Sun. The term ‘one day’ is determined by the time the Earth takes to rotate once on its axis and includes both daytime and nighttime. So, Sun does not go anywhere, it is we (Earth) who rotates!

Read More: http://bit.ly/VideoAuditandInspection

Content: Jig vs Fixture

Objective

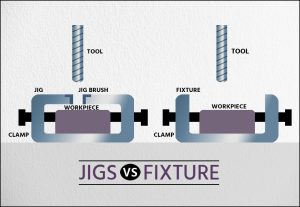

In metalworking and woodworking, both jigs and fixtures are essential tools. They are often confused with each other; however, they are two different tools with different functions. A jig is a type of tool that is used to control the location and/or motion of another tool. A fixture, on the other hand, is a work-holding or support device, used to hold the work in place.

Once you read this blog, you will understand, what is a Jig, what is a Fixture, the difference between them and how to effectively utilize them in the organization.

Read More: https://bit.ly/DifferenceOldNewFMEA

Definition: IATF 16949: 2016

Total Productive Maintenance (Cl 3.0): A system of maintaining and improving the integrity of production and quality systems through machines. equipment, processes, and employees that add value to the organization

Manufacturing Services (Cl 3.0): Companies that test, manufacture. distribute, and provide repair services for components and assemblies

Read More: https://bit.ly/DiffVisionMission

Detailed Information

The major difference between Jig and Fixture is that Jig is a type of tool used to control the location or motion of another tool. Whereas Fixture is a support or work-holding device used to hold work in place. In metal and woodworking, both jigs and fixtures are essential tools used. It is used to increase the productivity of the various parts produced in the industries.

The major difference between Jig and Fixture is that Jig is a type of tool used to control the location or motion of another tool. Whereas Fixture is a support or work-holding device used to hold work in place. In metal and woodworking, both jigs and fixtures are essential tools used. It is used to increase the productivity of the various parts produced in the industries.

Read More: https://bit.ly/BusinessPlanObjectives

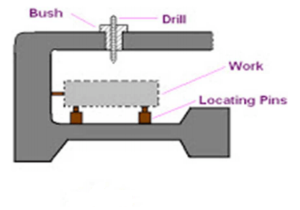

Jigs are the work-holding devices that hold, support, and locate the workpiece and guide the cutting tool/ tools to perform one or more specific operations. In other words, it can be defined as the device used to hold and guide the cutting tool.

The main purpose of the jig is to provide accuracy, interchangeability and repeatability in the manufacturing process. Here are some common types of Jigs:

The main purpose of the jig is to provide accuracy, interchangeability and repeatability in the manufacturing process. Here are some common types of Jigs:

- Template jigs

- Plate drill jigs

- Angle plate jigs

- Channel jigs

- Box jigs

- Leaf jigs

- Other jigs used for drill bushing, slotting and guiding other tools

Read More: http://bit.ly/SPCandMSA

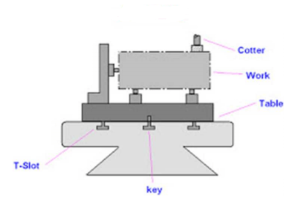

Fixtures are the devices that only hold, support and locate the workpiece in the desired position to provide accuracy, interchangeability and repeatability.

The main purpose of a fixture is to ensure that all parts produced using the same fixture will maintain the same level of conformity and interchangeability.

They are mostly used in specific operations, such as milling, slotting, grinding or shaping. There are several fixtures designs available:

They are mostly used in specific operations, such as milling, slotting, grinding or shaping. There are several fixtures designs available:

- Plate fixture

- Angle plate fixture

- Vice-jaw fixture

- Indexing fixture

- Milling fixture

- Profile fixture

Read More: http://bit.ly/CommonSpecialCause

Difference Between Jig and Fixture

Both Jig and Fixture have some commonalities too like improving productivity, reducing human effort, reducing error due to human endurance, facilitating interchangeability and minimizing rejection.

Some of the key differences are as follows.

| S.No. | JIG | FIXTURE |

| 1 | Controls and guides the machining tool | Holds and supports the component precisely for machining operations |

| 2 | Ensures accuracy, repeatability and interchangeability | Provides a reduction in error by holding a component firmly on a table |

| 3 | Are usually on the lighter side | Are bulky, rigid and heavy |

| 4 | Some of the standard Jig functions are drilling, reaming, tapping and boring | Are used explicitly in milling machines, slotting machines and shapers |

| 5 | Comparatively costly | Are not that costly compared to Jigs |

| 6 | Require intricate design operations | Design operations are relatively less complicated |

Read More: http://bit.ly/VariableAttributeControlChart

Conclusion

Though used as synonyms, Jigs and Fixtures are very different tools. Jigs are made to guide the cutting tool while the workpiece remains stationary and fixtures are made to guide the workpiece while the machining tool remains in place. Furthermore, they are easier to use, even by semi-skilled operators. And since they are standardized, they ensure that every part produced is consistent, reducing the risk of human error.

Though used as synonyms, Jigs and Fixtures are very different tools. Jigs are made to guide the cutting tool while the workpiece remains stationary and fixtures are made to guide the workpiece while the machining tool remains in place. Furthermore, they are easier to use, even by semi-skilled operators. And since they are standardized, they ensure that every part produced is consistent, reducing the risk of human error.

Read More: https://bit.ly/DifferenceCrandCSR

References:

ISO 9001: 2015

ISO 9002: 2016

ISO 9004: 2018

IATF 16949: 2016

Industry Experts

This is the 185th article of this Quality Management series. Every weekend, you will find useful information that will make your Management System journey Productive. Please share it with your colleagues too.

In the words of Albert Einstein, “The important thing is never to stop questioning.” I invite you to ask anything about the above subject. Questions and answers are the lifeblood of learning, and we are all learning. I will answer all questions to the best of my ability and promise to keep personal information confidential.

Your genuine feedback and response are extremely valuable. Please suggest topics for the coming weeks.

Leave a Reply

You must be logged in to post a comment.