“You have to be odd to be number one.” — Dr Seuss

Introduction

Chinese whispers is an internationally popular game in which messages are whispered from person to person and then the original and final messages are compared. This sequential modification of information is called transmission chaining in the context of cultural evolution research and is primarily used to identify the type of information that is more easily passed on from one person to another. The key objective is analyzing the confusion, gossip spread and inaccuracies created when the information reaches to the last person.

Content: MSA: What is GRR%?

- What is GRR%?

- What is its purpose?

- How to interpret it?

- Conclusion

Objective

Measurement Systems Analysis, as part of the Statistical Process Control practices, has been widely used in many industries, especially those related to the automotive sector.

The key objective of MSA study is to identify the contribution of measurement system error in the overall variation in the process or product, GRR% is an output of the statistical study which helps the user to understand the contribution of the measurement system error and possible actions.

Once you go through the article, you will understand the meaning of GRR%, what is its purpose, how to interpret it and how to make its best use.

Read More: http://bit.ly/VariableAttributeStudy

Definition: MSA: AIAG Manual 4th Edition

Repeatability: Variations in the measurements obtained with one measuring instrument when used several times by an appraiser while measuring the identical characteristic on the same part.

Reproducibility: Variation in the average of the measurements made by different appraisers using the same gauge when measuring a characteristic on a part.

Bias: The difference between the observed average of measurements and the reference value.

Linearity: The change in bias over the normal operating range. A systematic error component of the measurement system.

Stability (Drift): The total variation in the measurement obtained with the measurement system on the same master or parts when measuring a single characteristic over an extended time period. Stability is the change in bias over time.

Read More: http://bit.ly/CommonSpecialCause

Detailed Information

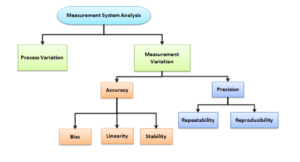

The purpose of Measurement System Analysis is to qualify a measurement system for use by quantifying its accuracy, precision, and stability.

The key purpose of conducting the study is to understand that,

- Whether our measurement system variability is small compared with the process variability.

- Whether our measurement system is capable of distinguishing between different parts.

Read More: https://bit.ly/MSAndc

In any measurement system, there can be 5 different errors. They are,

Bias

Bias- Stability

- Linearity

- Repeatability

- Reproducibility

Read More: http://bit.ly/SPCandMSA

What is GRR%?

Gauge R&R (gauge repeatability and reproducibility) is the combined estimate of measurement system repeatability and reproducibility. Gauge R&R study determines whether the measurement system is acceptable or not.

Gauge repeatability and reproducibility study determine the contribution of the measurement system variation within the total variation. Total variation is the combined effect of measurement system variation (due to equipment and appraiser variation) and the manufacturing process variation.

GRR study predicts the percentage of error present in the measurement system and identifies the source of variations (equipment and appraiser) to improve the quality of collected data. High quality of collected data will lead to effective decision making, improve the quality of product/process, and lesser chances of error.

- Repeatability: Repeatability is the variation between successive measurements of the same part or trait by the same person using the same gauge. In other words, how much variation do we see in measurements taken by the same person, on the same part, using the same tool?

- Reproducibility: Reproducibility is the difference in the average of the measurements made by different people using the same instrument when measuring the identical characteristics on the same part. In other words, how much variation do we see in measurements taken by different people on the same part using the same tool?

Gauge R&R formula based on Tolerance:

Repeatability= (EV/Tolerance) x 100%

Reproducibility= (AV/Tolerance) x 100%

where EV is equipment variation and AV is appraiser variation.

Gauge R&R formula based on Total Variation:

Repeatability= (EV/Total Variation – TV) x 100%

Reproducibility= (AV/Total Variation – TV) x 100%

where EV is equipment variation and AV is appraiser variation.

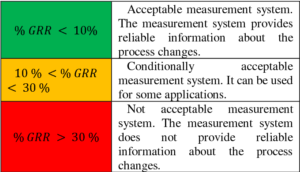

Gage R & R acceptance criteria based on the estimated value of repeatability and reproducibility (%R&R) of the measurement system.

Read More: http://bit.ly/TypeITypeIIError

When Repeatability is larger compared to Reproducibility then:

- The gauge needs maintenance.

- The gauge should be redesigned for more rigidity.

- The clamping or location for gauging needs to be improved.

- Excessive within-part variation.

When Reproducibility is larger compared to Repeatability then:

- The appraiser is not properly trained and needs better gauge use training.

- Incremental divisions on instrument are not clear/readable.

- Need fixture to provide consistency in gauge use.

Read More: https://bit.ly/MSASWIPE

Points to be considered while conducting GRR study:

- Forgetting that the Gauge R&R study is evaluating their measurement system and NOT their products. Gage R&R does not care about how good your products are. It only cares about how well you measure your products.

- Using only one part. If you only use one part, there cannot be any part variation, so people and equipment are the only source of variation.

Read More: http://bit.ly/BiasLinearity

Conclusion:

The purpose of the MSA study is to identify the possible error emanating from the measurement system. Either the error should be within target or the user should have a justified reason to have more measurement error. Whatever decisions are being taken; it should be in context to the measurement system. In short, the smaller the uncertainty, the more reliable the data.

The key goal is to minimize the amount of variation and error introduced by measurement so that the user can focus on part variation. This, of course, leads back into the other root causes of variation: process, machines, and materials.

Read More: http://bit.ly/CommonSpecialCause

Industry Challenges:

- How many users of the MSA study have clarity regarding GRR%?

- How often the logical and systematic justification is provided when GRR% is more than 10%?

- If it is always acceptable if GRR% is less than 10%?

References:

MSA AIAG Manual 4th Edition

Industry Experts

This is the 211th article of this Quality Management series. Every weekend, you will find useful information that will make your Management System journey Productive. Please share it with your colleagues too.

In the words of Albert Einstein, “The important thing is never to stop questioning.” I invite you to ask anything about the above subject. Questions and answers are the lifeblood of learning, and we are all learning. I will answer all questions to the best of my ability and promise to keep personal information confidential.

Leave a Reply

You must be logged in to post a comment.