Business continuity of Supply Chain post-COVID 19

The supply chain is like nature, it is all around us– Dave Waters

The entire world including individuals, organizations, society and nations are badly impacted by COVID 19. It has opened a pandora box of a new set of challenges which no one had ever thought in their wildest imagination. But all these confrontations are real and organizations need to find temporary and long-term solutions in this ‘New Normal’ situation.

Depending on the type of industry, the challenges may be local or global. In the manufacturing sector, almost entire world is dependent on China. Its role as ‘World’s Factory’ is creating more shivers to the world’s economy than its benefits over the last 2 decades.

As per the Darwinian theory, it is the time for ‘Survival of the fittest’. All of a sudden, the concept of globalization is being considered as a jinx and global biggest economies have started looking inwards to become self-reliant!

The manufacturing sector is the hardest hit segment as it is dependent upon the supply chain which has completely disbanded for the last few months. While it is hard to scatter, it is even harder to work again as a seamless team. Kristin Dziczek, Vice President at the Center for Automotive Research has rightly said, ‘We need ALL the parts to make a car, we can’t do it with 99.9%.’

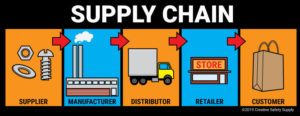

While specifically focusing on Automotive Manufacturing Sector, the challenges in different parts of the supply chain are quite different. If we bifurcate the entire Automotive Supply Chain, the following will be the typical scenario & their challenges.

| Supply Chain | Activity | Few Challenges |

| Consumer | Who purchases the vehicle and use it |

High cost of EURO 6 vehicles Job losses / Business stagnation Uncertain future Travel restrictions |

| Dealer/Service centre | Who purchases from OEM, sells the vehicle to Consumer and offer services post-delivery |

High inventory of EURO 4 vehicles No/Less demand for new vehicles No servicing & purchase of accessory parts Poor ROI on investment |

| OEM

(4W / 2W) |

Gets components from Tier 1, manufactures few components themselves, assembles and sells to Dealer. |

Huge investment on EURO 6 technology & Electric Vehicles No import of components No / Meagre demand for next quarter The inventory pile-up of EURO 4 vehicles Inadequate government support |

| Tier 1 | Procures components & raw material from tier 2/3 & 4, manufactures few components, do value addition, make assemblies and supply to OEM’s |

Non-availability of skilled manpower Huge loans & pressure of cost-cutting Profits for the financial year decimated Fluctuating demand from OEM |

| Tier 2 | Procures components & raw material from tier 3/4, manufactures few components, do value addition, make sub-assemblies and supply to OEM’s |

Low-profit margin resulting in bankruptcy like situation Non-availability of manpower The pressure of cost-cutting from tier one Delayed payment from tier 1 |

| Tier 3 | Generally, outsource process like tool room, electroplating, Heat Treatment etc. for tier 2 and 1 |

Erratic business Inadequate infrastructure No / Minimal government support Dependent on Tier 1 & 2 |

| Tier 4 | Raw material manufacturers like Steel, Rubber, Chemicals etc.

|

Huge investments The high cost of restarting the production Import of raw material Efficiency goes down when not running at full potential |

The entire automotive supply chain is undergoing umpteen Business Continuity challenges. All of them can be broadly divided into 4 key segments. Business, Financial, Interested parties and Internal Processes.

Possible Challenges:

Business Perspective:

VUCA:

- Volatile: Unpredictability of demand, High cost of production

- Uncertain: Uneven customer expectations,

- Complex: Insecure future

- Ambiguous: Broken supply chain (few industrial areas are operating but many are not), Government policies

Financial Perspective:

- Cost optimization pressure

- Bad bank loans

- Companies are getting bankrupt during the lockdown and not opening

- Cash Flow issues

- CAPEX (Capital Expenditure) freeze

Interested parties Perspective:

- Strategy/Vision lacking in the majority of Tier 1, 2, 3

- Travel restrictions (Air travel closed)

- Inadequate manpower (migrant workers)

- Indifferent government policies

- Fear and uncertainty among the people

- Job losses

- Poor communication channel

Internal processes Perspective:

- Vision of top management

- Weak Quality Management System

- No understanding/experience, how to synchronize and restart the business processes

- Inadequate Emergency preparedness

- Poor communication channel

- Shortage of competent manpower

- Non-availability of raw material

- Logistics issue: How to deliver material/Product

Possible solutions:

Business Perspective:

- Involvement & commitment of top management

- Review the concept of dependency on one country/supplier for cost-benefit

- Being agile towards customers, employees and interested parties

- Think about IoT (Internet of Things), digital solution, low-cost automation

Financial Perspective:

- Review the price model; how cost can be cut across the supply chain so that consumer can afford the product and demand can be escalated

- Unfreezing the CAPEX for low-cost automation, digitalization, setting up alternate communication channels

Interested parties Perspective:

- Communication, Communication, Communication

- Empathy

- Sharing their concerns and understanding it of the other interested parties and coming to a common ground

- Sharing the resources wherever possible

- Find alternate ways for material movement across the supply chain

Internal processes Perspective:

- Acknowledge that problem is existing

- Understanding the voice of your employees

- Rebuilding the morale of the team

- Low-cost automation

- Understanding the power of the digital medium and utilize it to the fullest

- Think out of the box and create confidence in consumers so that demand can be regenerated

All the above are some of the grave glitches which organizations can foresee now and there will be many more which will be visible in the following months. Although organizations have faced many challenges in the recent past (Year 2008 Recession) and have come out strongly and wisely, this is another opportunity for them to register in the history, how industries have battled this pandemic and have come out of it with maturity and dignity.

References:

ISO 22301: 2019: Business Continuity Management System

ISO 9001: 2015

IATF 16949: 2016

This is the 57th article of this Quality Management series. Every weekend, you will find useful information that will make your Management System journey Productive. Please share it with your colleagues too.

Your genuine feedback and response are extremely valuable. Please suggest topics for the coming weeks.

Leave a Reply

You must be logged in to post a comment.